This yarn lubrication device can be applied both on knitting machines than on circular

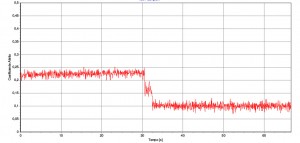

This yarn lubrication device can be applied both on knitting machines than on circular  knitting machines. The yarn during the phase of “knitting” flows on a specific porous ceramic sintered material which allows a perfect yarn lubrication increasing its smoothness and reducing broken needles and machine downtime, lubricating itself perfectly and dramatically decreasing the coefficient of friction of the yarn, increasing its smoothness.

knitting machines. The yarn during the phase of “knitting” flows on a specific porous ceramic sintered material which allows a perfect yarn lubrication increasing its smoothness and reducing broken needles and machine downtime, lubricating itself perfectly and dramatically decreasing the coefficient of friction of the yarn, increasing its smoothness.

Advantages:

The advantages in productivity and quality obtainable on knitting machines are the following:

– Significant decrease on circular knitting machines in the consumption of needles and sinkers.

– Increase the productivity of flat knitting machines due to the elimination of the phase winding / waxing of the yarn before it is put on the machine.

– Significant decrease of static electricity in the yarn.

– Significant decrease of dust.

– Increase the tenacity and the smoothness of the yarn during work process.

Application principle:

LUBRY KNIT comes with a convenient and simple oil supply tank incorporated in the device itself with a capacity of 200 cc or 500 cc that does not require topping up for several working days.

LUBRY KNIT can be mounted on any type of knitting machine and does not require specific adjustments based on the type of the yarn.