The technological innovation introduced in the socks industry machines more powerful and

The technological innovation introduced in the socks industry machines more powerful and  faster, however in many cases the quality of the yarn is not able to follow the speed of the new machines creating many problems during the manufacturing process such as defects in the final products or broken yarns.

faster, however in many cases the quality of the yarn is not able to follow the speed of the new machines creating many problems during the manufacturing process such as defects in the final products or broken yarns.

Processes such as yarn winding, before production , are on the daily agenda, raising significantly the costs and production times. NUOVA RIMATES, with the device LUBRY SOCK, introduces an highly effective solution for all these issues.

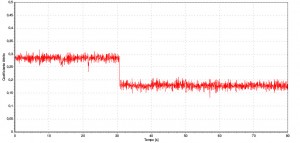

This yarn lubrication device can be applied on all machines for the production of men and women socks. The yarn before entering the machine flows on a porous ceramic sintered material, becoming perfectly lubricated and decreasing drastically the coefficient of friction of the yarn, increasing its smoothness.

Advantages:

The advantages in productivity and quality obtainable on socks machines are the following:

– Significant decrease of the consumption of needles and sinkers.

– Increase the productivity due to the elimination of the phase winding / waxing of the yarn before it is putted in the machine.

– Significant decrease of static electricity in the yarn.

– Significant decrease of dust.

– Increase the tenacity and the smoothness of the yarn during work process.

Application principle:

LUBRY SOCK comes with a convenient and simple oil supply tank incorporated in the device itself with a capacity of 200 cc or 500 cc based on the requirements and on the machine type.

LUBRY SOCK can be mounted on any type of socks machine and does not require specific adjustments based on the type of the yarn.